Fields Handled by Ichikin

Polymer Chemistry

ICHIKIN's machines supports various scenes in everyday life.

The machines developed by our company is widely used in the manufacturing processes of many products, including smartphones and tablets that are prevalent worldwide, advanced devices for high-speed communications, and lithium-ion batteries at the heart of next-generation electric vehicles.

Founded in 1954, we started off by producing and selling textile machinery.

We specialized in the field of dyeing and finishing, excelling in the technologies of washing, squeezing, spreading, and drying, and our heat-setting equipment became a major success worldwide.

In the late 1990s, with the trend towards digitalization, we applied these technologies to the field of polymer chemistry, developing them into coating, stretching, and laminating technologies for functional films. Our long-accumulated expertise in controlling heat, wind, and water, highly acclaimed by our customers, is based on high-precision temperature and wind speed control, along with substrate transport technology that includes liquid processing.

Amid the global demand for efforts towards the SDGs (Sustainable Development Goals), we aim to be a company that contributes to our customers and communities with environmental preservation on a global scale in mind.

ICHIKIN's machines supports various scenes in everyday life.

Polarizing film, retardation film, etc.

Flexible printed circuit boards, insulation materials, etc.

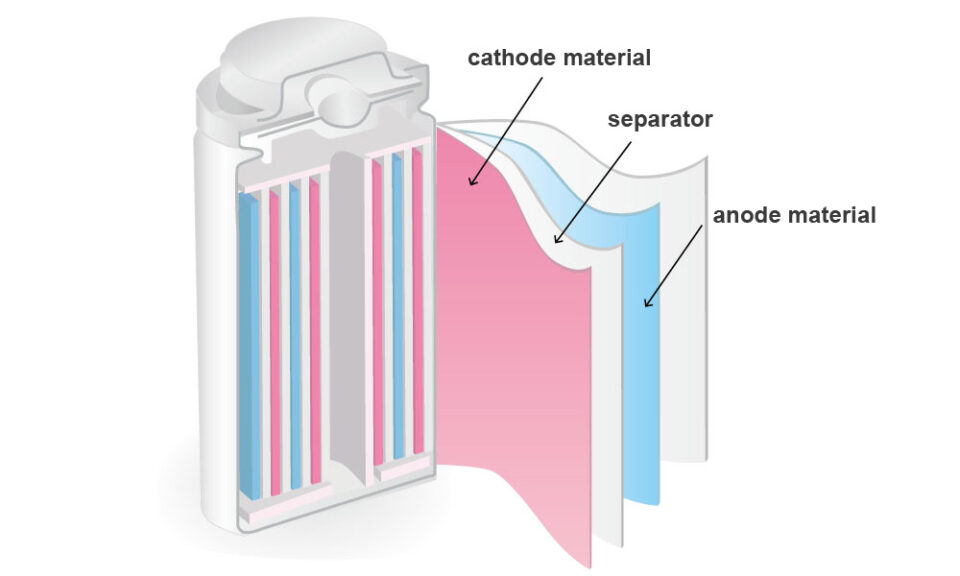

Separators, cathode materials, anode materials, etc.

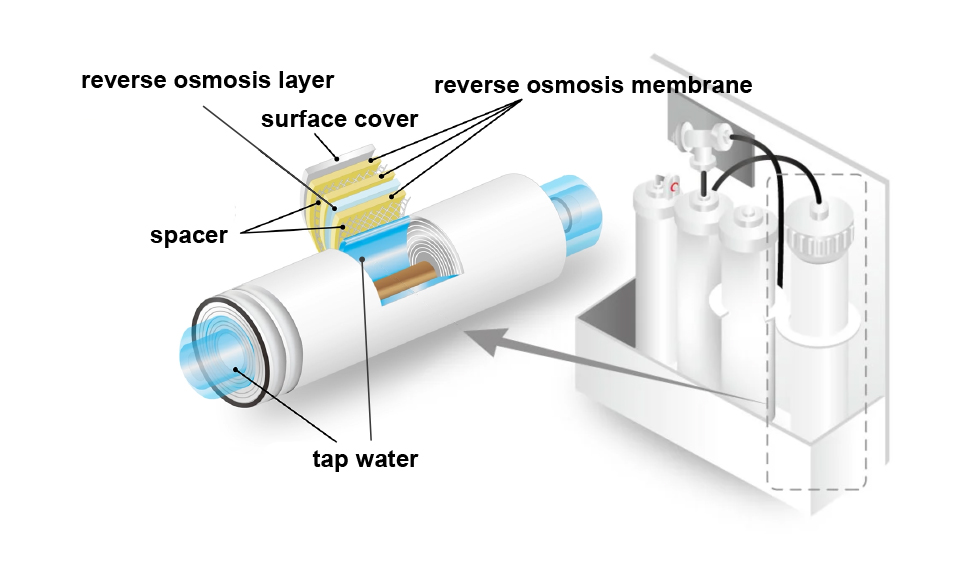

Ion exchange membranes, water treatment membranes, separation membranes, etc.

Artificial dialysis filters, poultice material, mask filters, etc.

Tire cords, carbon fibers, glass fibers, etc.

Heat-resistant films, gas barrier films, packaging films, etc.

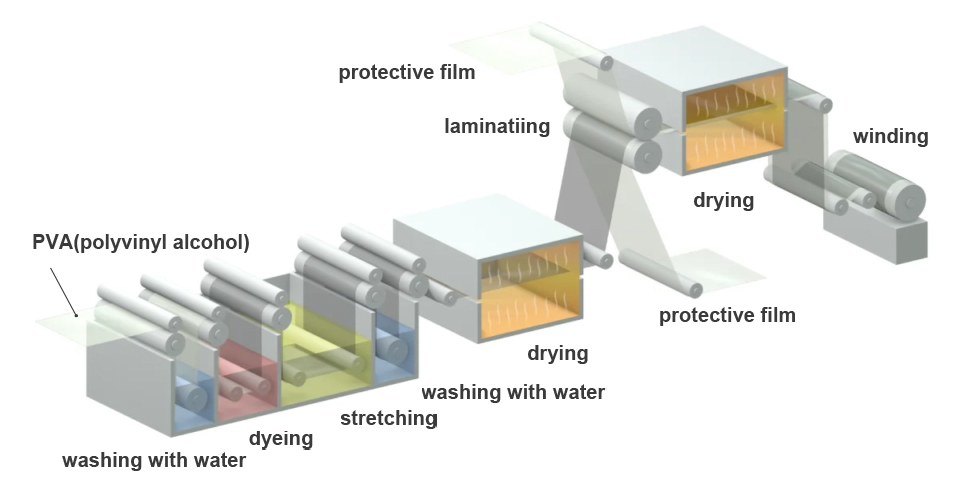

We manufacture machines used to produce polarizing films and retardation films found in LCD panels for devices such as TVs and computers.

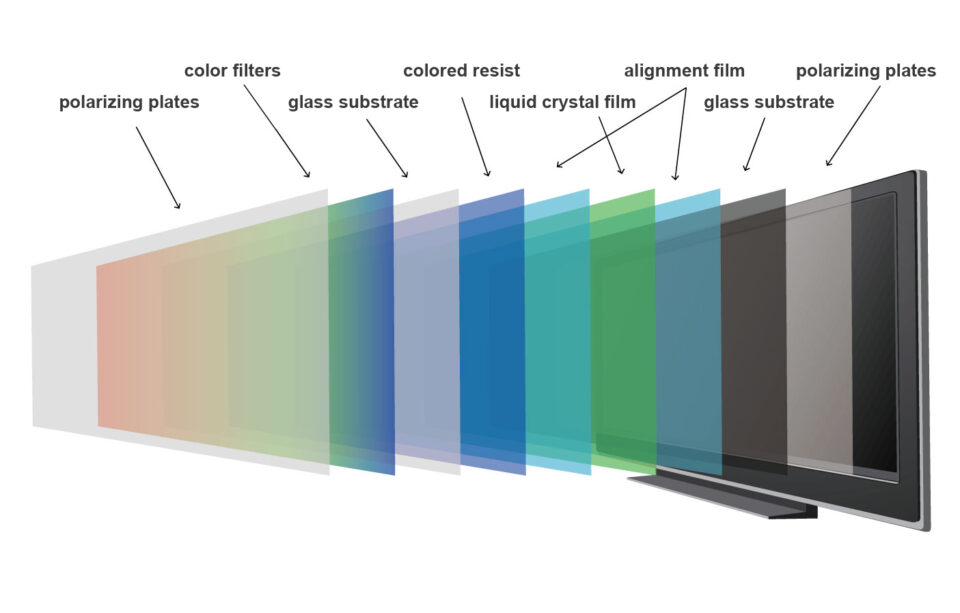

Liquid crystal panels are composed of various elements such as polarizing plates and glass substrates layered together.

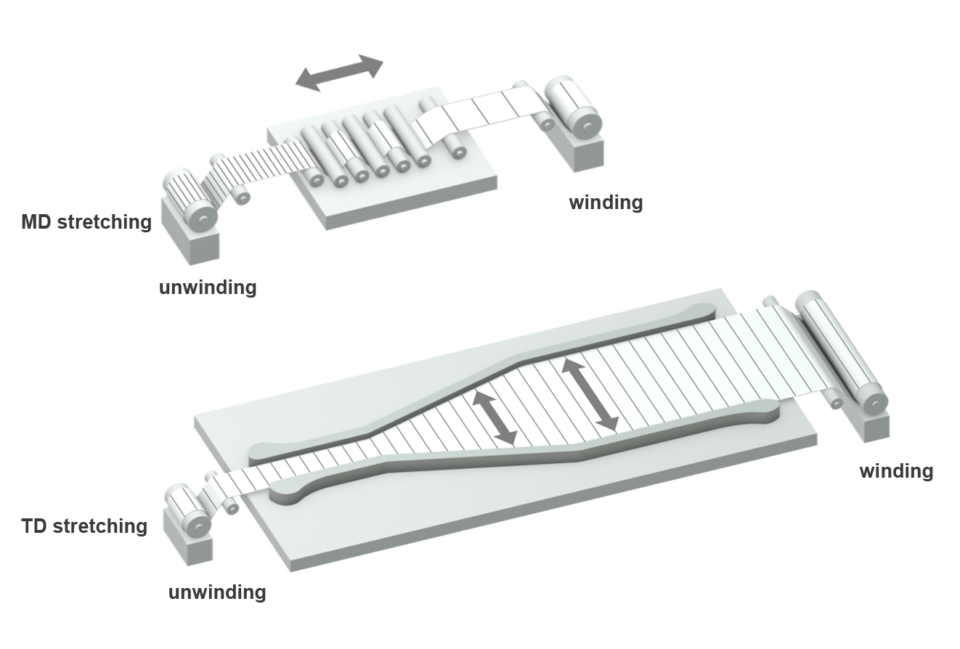

Among these, polarizing plates undergo various processes such as washing, dyeing, stretching, drying, and application.

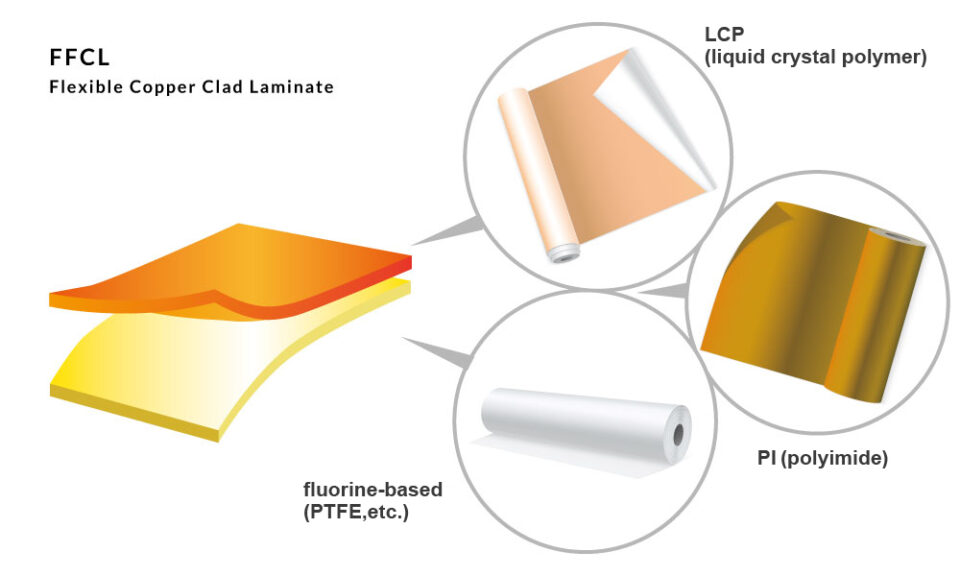

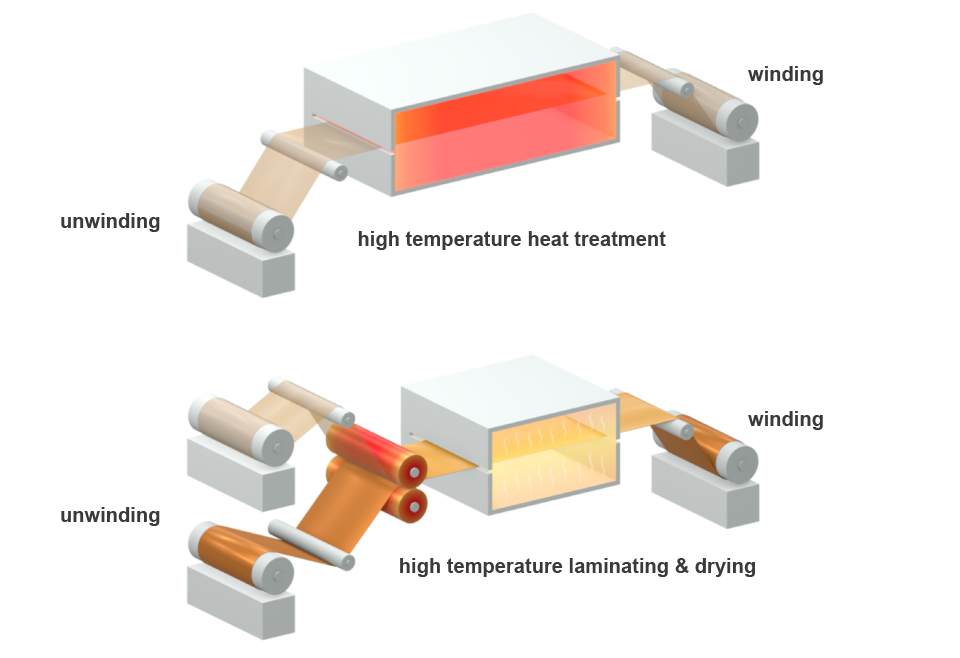

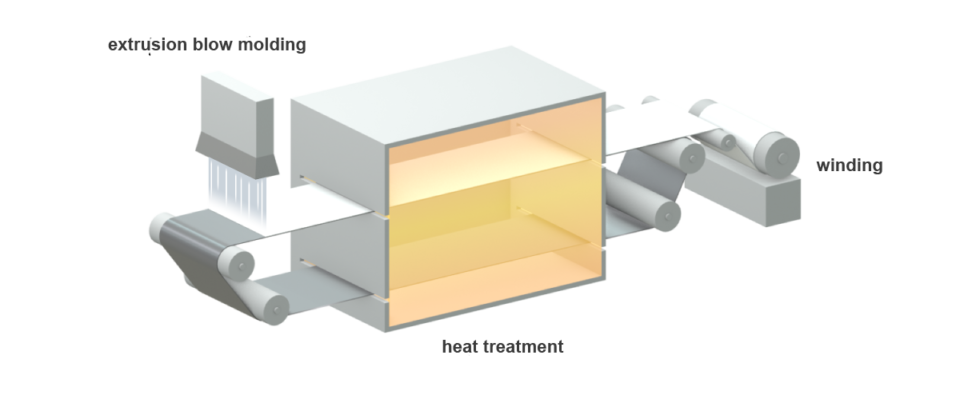

We manufacture machines for producing films for electronic materials such as Flexible Printed Circuit Boards (FPC) used in smartphones and other devices.

Flexible Printed Circuit Boards (FPC), essential for the miniaturization, lightweighting, and thinning of electronic devices, are manufactured through high-temperature heat treatment and drying of materials called FCCL (Flexible Copper Clad Laminate) used for FPCs.

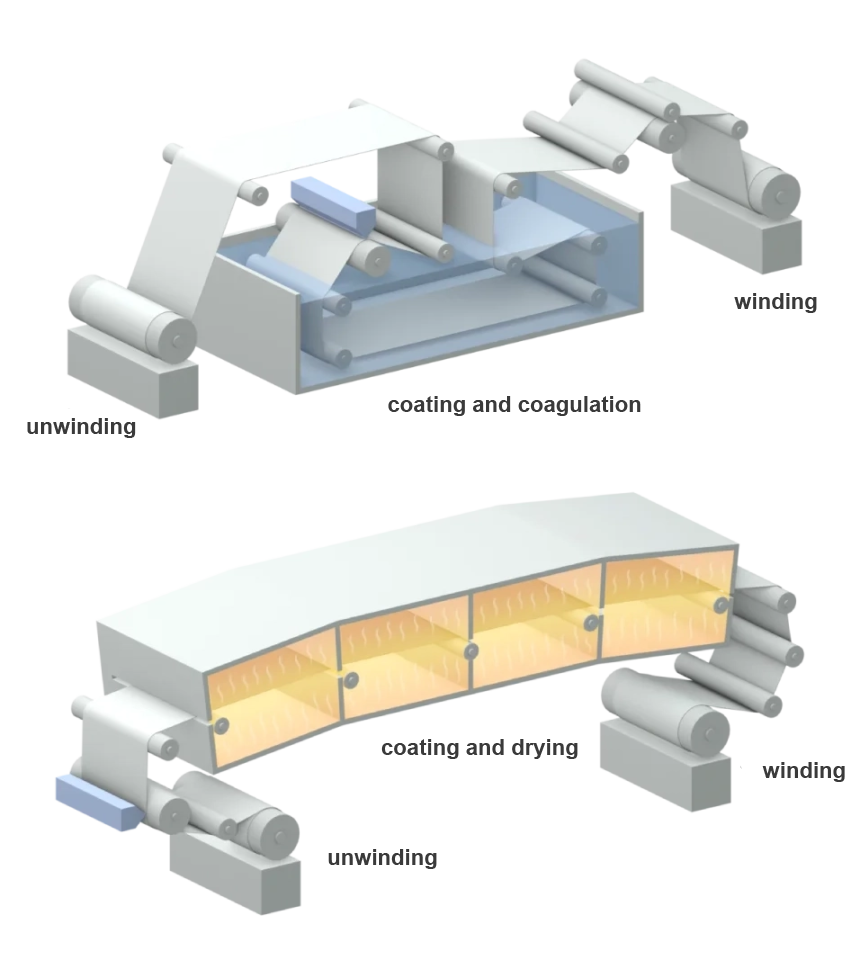

We manufacture machines for producing separators and cathode/anode materials used in lithium-ion batteries and other applications.

The main components of lithium-ion batteries, namely cathode materials, anode materials, and separators, are manufactured using coating and stretching techniques.

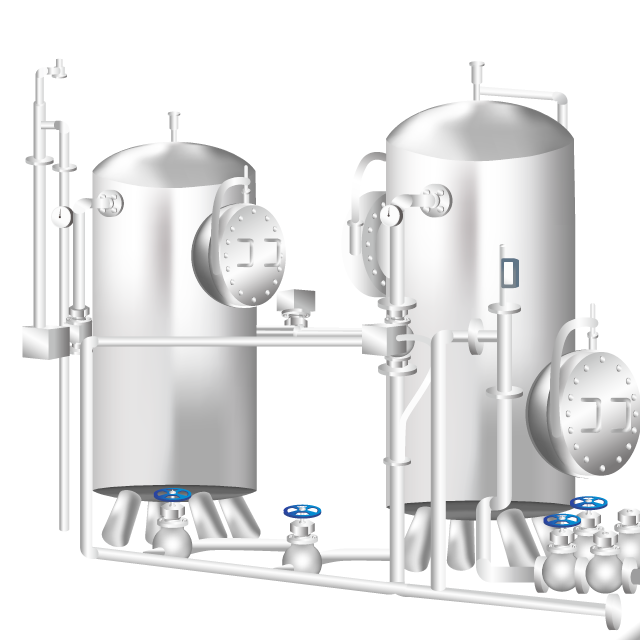

We manufacture machines for producing high-performance membranes such as ion exchange membranes, water treatment membranes, and separation membranes used in devices like purification systems of cleaning water.

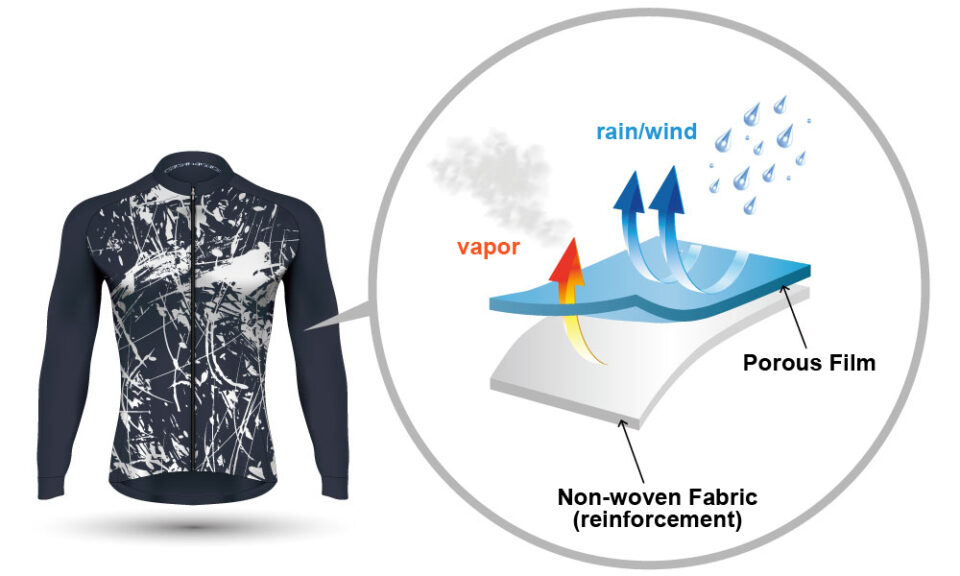

Porous films with both moisture permeability and waterproofing properties are manufactured through processes such as coating, solidification, and drying.

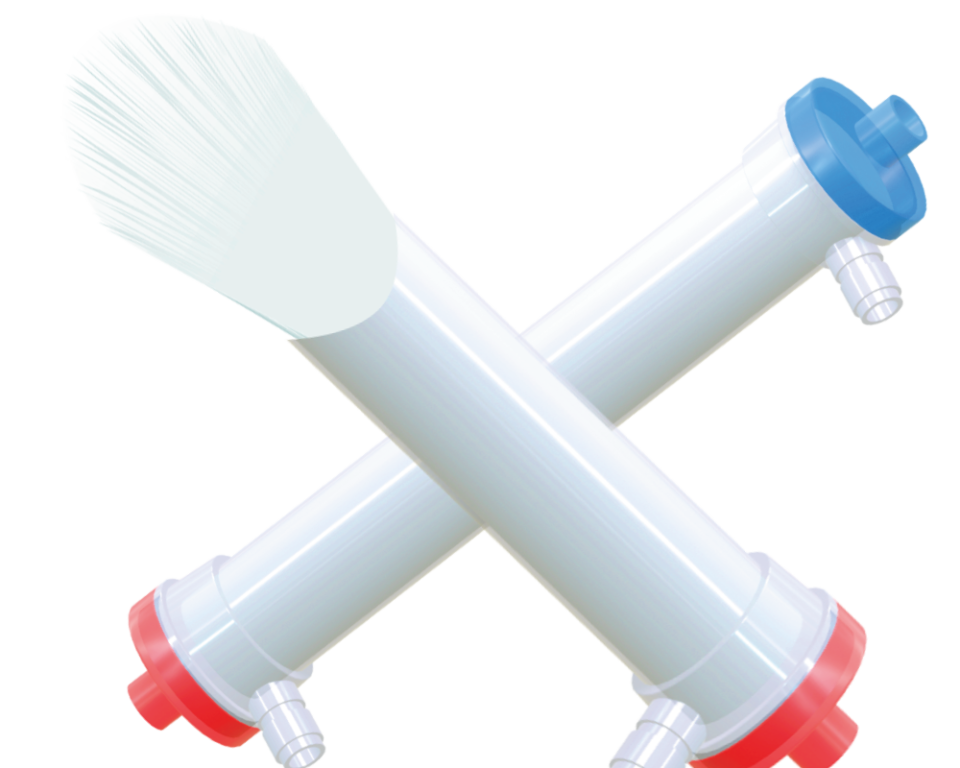

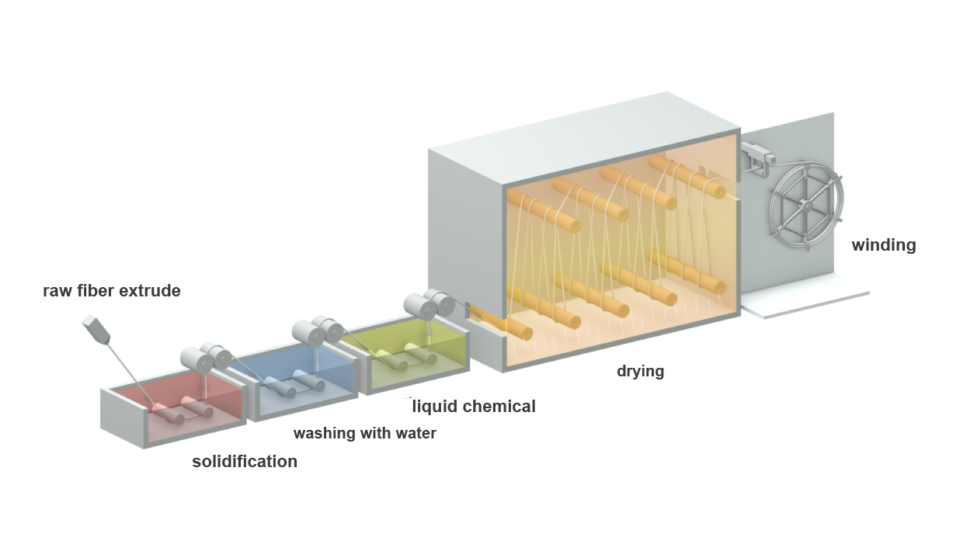

We manufacture machines for processing medical-grade materials such as non-woven fabric used in masks and hollow fibers used in dialyzers for artificial dialysis.

-960x576.png)

Non-woven fabric is manufactured by entangling fibers together or bonding them with heat treatment and other methods.

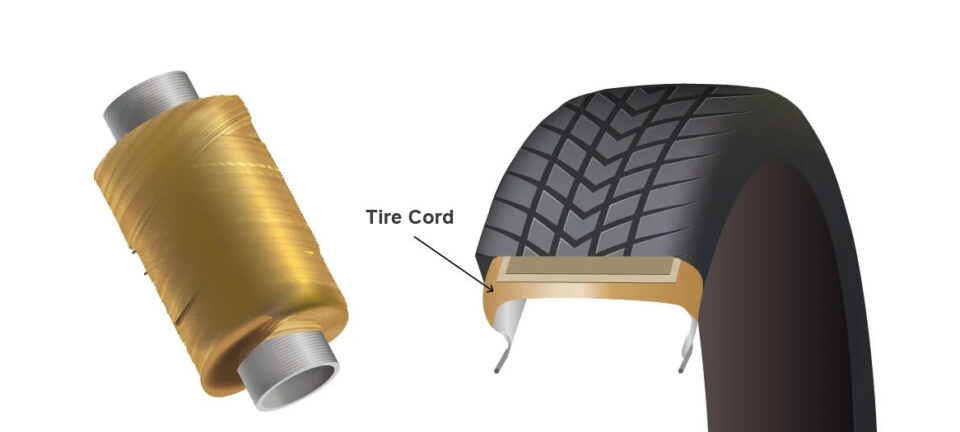

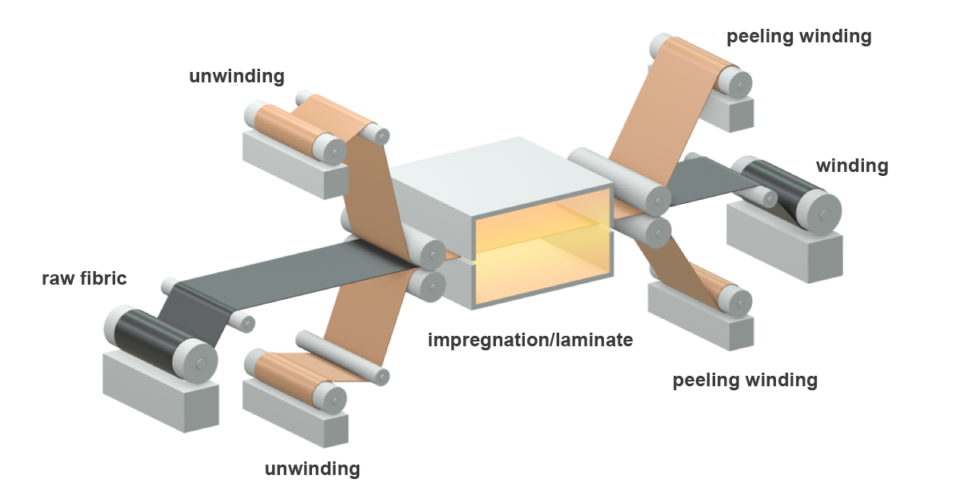

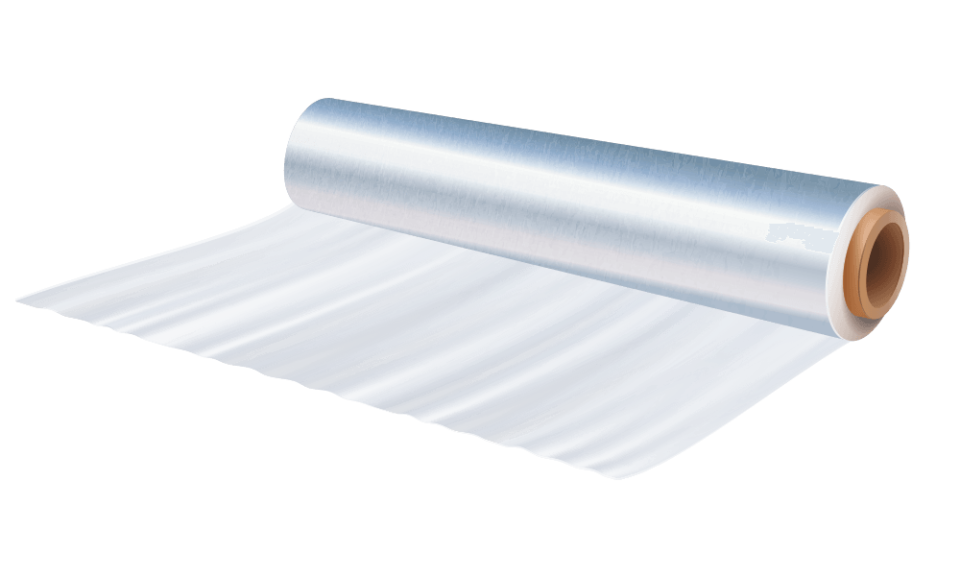

We manufacture machines to produce tire cords used in tire construction, as well as carbon fiber prepreg used in buildings, sports equipment, aerospace, and spacecraft.

A tire cord is a fiber thread used in the framework of tires, capable of withstanding complex deformations and maintaining its basic shape. It is manufactured through repeated processes of impregnation and drying.

Prepreg is manufactured by impregnating resin into carbon fibers arranged in sheet form.

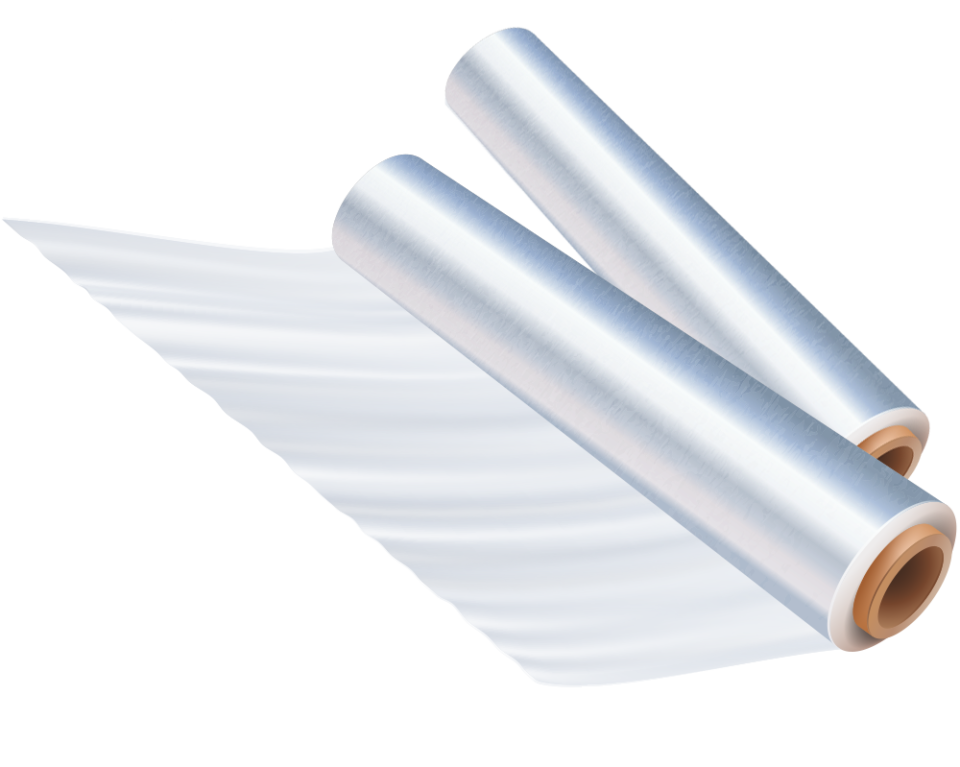

We manufacture machines to produce heat-resistant films and gas barrier films used in the food industry, as well as packaging films and shrink labels used for product packaging.

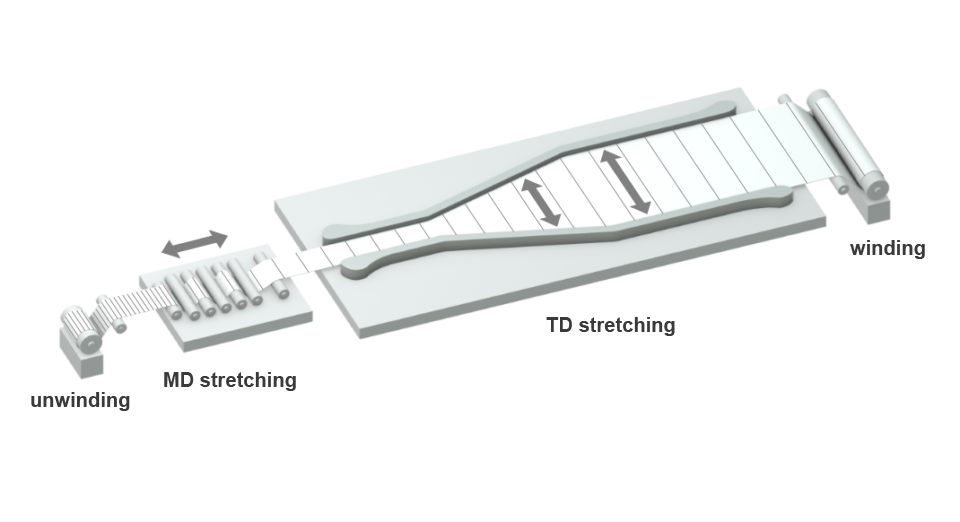

Functional films are manufactured by combining longitudinal stretching and transverse stretching to suit various applications.