Stretching Stretching Machines

Simultaneous Biaxial Stretching Machine

This machine stretches films in both the longitudinal and transverse directions simultaneously.

Stretching simultaneously produces films with uniform orientation.

修正-960x600.png)

Stretching both vertically and horizontally at the same time enables uniform orientation in both directions while suppressing crystallization!

-

Stretching of crystalline films

Typically, highly crystalline resins like PA (polyamide) crystallize further during the cooling process after longitudinal stretching.

This can lead to breakage in the subsequent transverse stretching process.

In simultaneous biaxial stretching, both directions are stretched at the same time before crystallization progresses, allowing for uniform stretching.

-

Stretching of microporous membranes

Ion exchange membranes, such as those used in lithium-ion battery separators and filtration membranes for liquids and gases, have nanometer-scale pores that form pathways for fluids.

The stretching process is applied to form these pores, and simultaneous biaxial stretching, which excels in suppressing crystallization and refining pore shape, can be advantageous. -

Stretching of optical films

In liquid crystal and organic EL panels, many films are used to enhance image clarity.

These films control light passage by altering molecular orientation, and stretching processes are applied for orientation control.

Simultaneous stretching is beneficial for enabling uniform or non-oriented films in such applications.

Applications & Features

- Applications

-

- Crystalline films (polyamide, etc.)

- Microporous films (ion exchange membranes, filtration membranes, collection membranes, etc.)

- Optical films

- Features

-

- Pantograph-type transporting mechanism of clips

- High-precision temperature and wind speed control

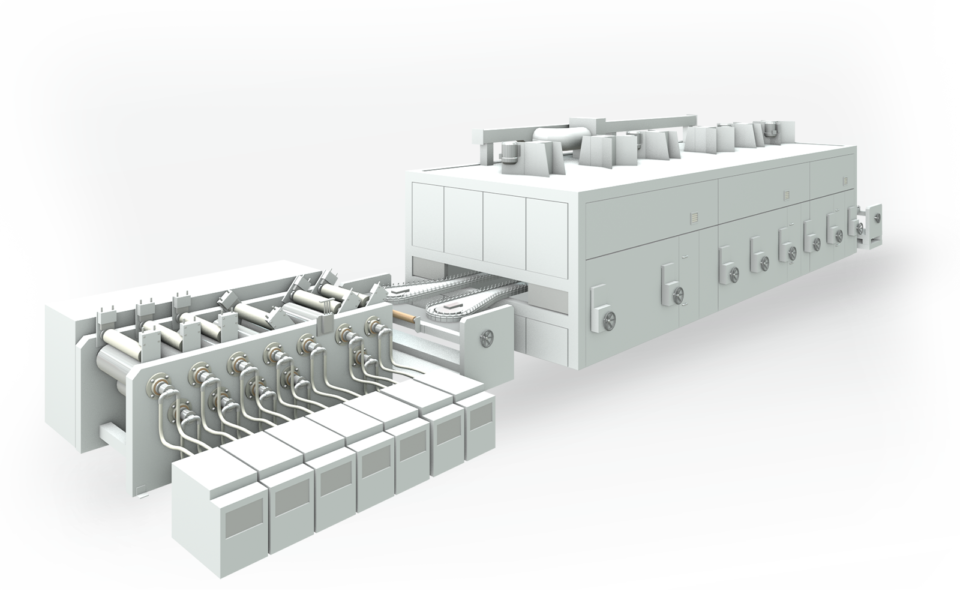

Successive Biaxial Stretching Machine

This machine stretches films in both the longitudinal and transverse directions separately.

It is widely applicable, from general-purpose to high-performance films.

The longitudinal and transverse directions are handled by separate machines. This enables a broad range of specifications, making it suitable for all types of production!

-

Applicable from general-purpose to high-performance films

The successive biaxial stretching machine features a simple device structure, a wide range of specifications, and low cost, making it widely used in all fields.

-

Excellent productivity with high speed and high strength

With longitudinal stretching done by rolls and transverse stretching by clips, the mechanism is very simple. This allows for high-speed, high-strength, and high-temperature stretching, resulting in excellent productivity.

Maintenance of the machine is relatively easy, contributing to the long lifespan of the machine.

-

Stretching of general-purpose films

Many films seen in everyday life undergo some form of stretching treatment.

These include food containers, packaging containers, wraps, bags, and labels, with many of them stretched either only longitudinally or only transversely.

Most are made from resins such as PE, PS, PET, and PP, and successive biaxial stretching machines are applied for large-scale mass production. -

Stretching of high-performance films

Many advanced materials, such as functional membranes, optical films, and electronic materials, utilize successive biaxial stretching.

By stretching longitudinally first and then transversely, it is possible to control orientation properly in one direction.

Moreover, since the longitudinal and transverse directions are independent, the speed, ratio, and temperature of each can be set widely and precisely, enhancing the functionality of the films.

Applications & Features

- Applications

-

- General-purpose films (PE, PS, PET, PP)

- Optical films (PVA, COP, TAC)

- High-temperature films (PTFE, LCP, PI, PEEK)

- Microporous films (ion exchange membranes, breathable waterproof membranes, filtration membranes, collection membranes)

- Features

-

- Longitudinal stretching uses a thermal roll method. For non-contact methods, there are options like hot air blowing and floating methods.

- Transverse stretching uses a clip method. We offer clip designs tailored to the properties of the film.

- High-precision temperature and wind speed control and film conveying technology

- We have extensive experience with high-temperature types (400°C)

修正-960x600.png)

-960x600.png)

-960x600.png)

-1-960x600.png)